Within any CDF series film, thinner films are generally used for finer detail, thinner ink deposit applications on fine screen mesh, whereas thicker films are used on coarser mesh when circumstances demand thicker ink deposits inherent to such mesh/stencil combinations.

Exposure Step Test Video 4Mb 2 minutes

"How Does Capillary Film Work" video 95 Mb 17 minutes

Capillary Film Cross Reference

Capillary Film Cross Reference

Ordering Information

Building Thick Film Stencils for Special Effects Printing

Direct Film Troubleshooting Checklist

EZ-50 Orange

Tech

Data Sheet

Tech

Data Sheet

Product

Fact Sheet

Product

Fact Sheet Tech

Data Sheet- Spanish

Tech

Data Sheet- Spanish

Ez-50

Orange Film for Imprinted Sportswear

Ez-50

Orange Film for Imprinted Sportswear

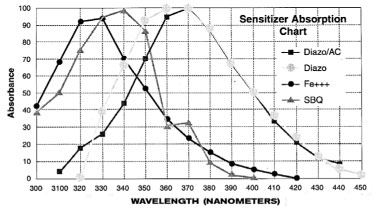

EZ-50 ORANGE is a pure photopolymer (SBQ), pre-sensitized capillary film appropriate for general sportswear printing. EZ-50 ORANGE is fast exposing and its high-contrast orange color “masks” halation and light scattering, thereby improving resolution without the need to use more-costly dyed mesh. EZ-50 ORANGE is coated on 300-gauge matte polyester. EZ-50 ORANGE (50 microns) is recommended for use with mesh counts ranging from 33 to 77 threads/cm. (86 – 196/inch.). EZ-50 ORANGE can be adhered with plain water, or with ORANGE ™ emulsion in the direct/indirect mode.

Features |

Benefits |

Consistent stencil thickness | Control of ink deposit and ink costs Consistent exposure time |

| Solvent resistant | Compatible with aggressive inks and solvents Reclaims easily without staining screen fabric |

| Transparent pink color | Easy stencil inspection and see-through registration |

| Easy to Use | Minimal training required Perfect stencils—every time |

| Fast exposure and processing | Fast stencil turnaround Dries faster than direct emulsion |

Formats: EZ-FILM-50 is available in prepackaged sheets ≈ 38 X 43

cm. (15 X 17 inches) and ≈ 43 X 60.9 cm. (17 X 24 inches), packaged

50 per box (2 X 25).

CDF® Vision- Dual cure capillary film enhances

cross-linking

CDF® Vision- Dual cure capillary film enhances

cross-linking

Product

Fact Sheet (English)

Product

Fact Sheet (English) Product

Fact Sheet (Spanish)

Product

Fact Sheet (Spanish)  Product

Fact Sheet (German)

Product

Fact Sheet (German)

Tech

Data Sheet

Tech

Data Sheet

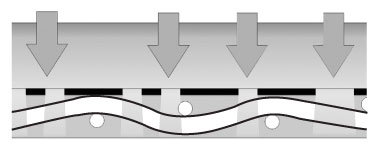

CDF Vision is a diazo dual-cure capillary film system.

Its special formulation controls

mesh penetration and enhances photo-polymerization, resulting in sharp printing

shoulders and mechanical durability. Particulate-size control reduces granularity

effects for optimal resolution and definition. Texturing agents impart a micro-structural

pattern to the bottom of the stencil, minimizing hydrostatic attraction to the

printing

stock under conditions of high humidity, and electrostatic attraction under low

humidity

conditions. CDF Vision is compatible with UVs, vinyls, and virtually all solvent-based

inks. Depending on the thickness selected, it is suited to such printing applications

as:

electronics circuit traces and membrane switches, halftones, CDs and DVDs, ceramic

decals, posters, and containers and bottles. CDF Vision is coated at thicknesses

of 15μ,18 μ, 20μ, 25μ, and 35μ.

| Features |

Benefits |

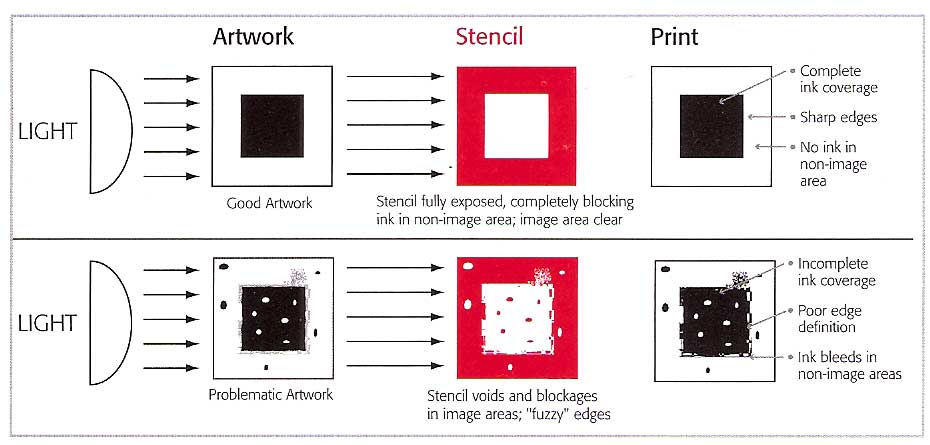

Excellent imaging properties | Superb acutance (printed edge definition) and resolution |

| Solvent resistant | Compatible with aggressive inks and solvents Reclaims easily without staining screen fabric |

| High-contrast color | Easy stencil inspection and see-through registration |

| Easy to Use | Minimal training required “Pre-coated” stencils = perfect stencils—every time Consistent exposure time Consistent stencil thickness = control of ink deposits—and ink costs Wet processing reduces drying time and pinholes; speeds production |

| Fast exposure and processing | Fast stencil turnaround Significantly less labor and production time Wide exposure latitude |

Formats: Available in rolls or custom-cut sheets (no mess, no waste!)

CDF® Lexar - Photopolymer (SBQ) capillary

film system

CDF® Lexar - Photopolymer (SBQ) capillary

film system

Product

Fact Sheet (English)

Product

Fact Sheet (English)  Product

Fact Sheet (Spanish)

Product

Fact Sheet (Spanish)  Product

Fact Sheet (German)

Product

Fact Sheet (German)

Tech

data sheet

Tech

data sheet

CDF Lexar is a series of SBQ (pure photopolymer) capillary films for use with solvent-based inks. CDF Lexar is easy to reclaim and well suited to the printing of flat-stock graphics, plastisols for textiles, POP displays, computer-to-screen (CTS), containers, printable adhesives, and advertising specialties. The red film is coated on a matte-surfaced polyester. This imparts a slight texture to the printing surface of the stencil, thus minimizing hydrostatic attraction to the printing stock under conditions of high humidity, and electrostatic attraction under low humidity conditions. CDF Lexar is coated at thicknesses of 15 (for mesh counts of 165 or more threads /cm. ≈ 419+ /in.), 20 (120 – 165 /cm. ) (305 – 419 /in.), 25 (100 – 150 /cm.) ( 255 – 380 /in.), 30 (90 – 165 /cm.) ( 230 – 419 /in.), 40 (77 – 120 /cm. ) (196 – 305 /in.), and 50 (33 – 77 /cm.) (86 – 196 /in.).

| Features |

Benefits |

Matte-surfaced polyester backing imparts textured surface to the printing surface of stencils | Minimizes hydrostatic attraction to printing stock under high humidity

conditions Minimizes electrostatic attraction under low humidity conditions |

| Good solvent resistance | Reclaims easily without staining screen fabric |

| Red, high-contrast color | Easy stencil inspection and see-through registration |

| Easy to Use | Minimal training required “Pre-coated” stencils = perfect stencils—every time Consistent exposure time Consistent stencil thickness = control of ink deposits—and ink costs Wet processing reduces drying time and pinholes; speeds production |

| Fast exposure and processing | Fast stencil turnaround Significantly less labor and production time Wide exposure latitude |

Formats: Available in rolls or custom-cut sheets (no mess, no waste!)

EZ-FILM™-30 - 30-Micron Textile Capillary Film, Priced as a Viable Alternative to Direct Emulsion; Fast Drying, Fast Exposing Pure Photopolymer (SBQ)

EZ-FILM™-30 - 30-Micron Textile Capillary Film, Priced as a Viable Alternative to Direct Emulsion; Fast Drying, Fast Exposing Pure Photopolymer (SBQ)

| Color | Solids | Viscosity | Shelf Life |

| Pink | 94% | none | 18 months in cool dry storage - Coated Screen Life 4 weeks |

Technical

Data Sheet

Technical

Data Sheet Tech

Data Sheet- Spanish

Tech

Data Sheet- Spanish

EZ-FILM-30 is ideal for standard textile printing using conventional, non-aqueous

garment printing inks. It is priced to be an economical alternative to direct

emulsion in material cost and because it offers significant savings in labor

and production time. EZ-FILM-30 is ideal for mesh counts ranging from 230 -

419 threads /inch (90 and 165/cm.). It is pink in color and coated on 300-gauge

matte-surface polyester. EZ-FILM-30 produces superb stencils quickly, consistently,

and with no mess or waste. At a controlled-coating thickness, EZ-FILM-30’s exposure time and ink deposit (with the same mesh count) is always constant.

It adheres perfectly, dries faster than direct emulsion, and exposes very quickly.

EZ-FILM-30 can be adhered with plain water or with QTX® direct

emulsion.

EZ-FILM-30 is sold in convenient prepackaged sheets.

| Features |

Benefits |

Easy to Use | Minimal training required Perfect stencils-every time |

| Fast processing and exposure | Dries faster than direct emulsion Fast stencil turnaround |

| Consistent stencil thickness | Control of ink deposit--and ink costs Consistent exposure time |

| Wet processing | Reduces potential for pinholes Speeds production |

| "Pre-coated" stencils | Significantly less labor and production time |

| Prepackaged film sheets | No mess, no waste Speeds up application. |

| Transparent pink color | Easy inspection and see-through registration |

FORMATS

EZ-FILM-30 is available in prepackaged sheets, 15 X 17 inches (≈ 38

X 43 cm.) and 17 X 24 inches (≈ 43 x 60.9 cm.)

| Light Source | ||||||

| Carbon Arc | EZ-FILM-30 | |||||

| 30 amps |

78 sec. | |||||

| 110 amps |

21 sec. | |||||

| Metal Halide | ||||||

| 1000 watts | 52 sec. | |||||

| 2000 watts | 27 sec. | |||||

| 3000 watts | 17 sec. | |||||

| 4000 watts | 13 sec. | |||||

| 5000 watts | 11 sec. | |||||

| 7000 watts | 9 sec. | |||||

| Pulsed Xenon | ||||||

| 2000 watts |

152 sec. | |||||

| 5000 watts | 61 sec. | |||||

| 8000 watts | 38 sec. | |||||

| Mercury Vapor | ||||||

| 1000 watts |

70 sec. | |||||

| 2000 watts | 33 sec. | |||||

| 4000 watts | 17 sec. | |||||

| Fluorescent Tubes* | ||||||

| 40 watts | 152 sec. | |||||

EXPOSURE VARIABLES FACTORS: variables affecting exposure time

| Mesh | Exposure Distance | Exposure Distance | ||||

| Dyed Mesh | 1.5-2.0 | 20”/50 cm |

0.25 | 56”/140 cm | 1.95 | |

| 24”/60 cm |

0.36 | 60”/150 cm | 2.25 | |||

| Imaging | 28”/70 cm |

0.49 | 72”/180 cm | 3.24 | ||

| Fine line reverse printing | 1.2 | 32”/80 cm |

0.64 | 84”/210 cm | 4.41 | |

| 36”/90 cm |

0.81 | 100”/250 cm | 6.25 | |||

| 40”/100 cm |

1.00 | |||||

| 44”/110 cm | 1.21 | |||||

| Adhering | 48”/120 cm |

1.44 | ||||

| Direct/Indirect Method using QTX® | 1.5 | 52”/130 cm |

1.69 | |||

| Taped-up Positives | ||||||

| Taped-up or montage positives, per layer | 1.1 | |||||

CDF/QT Thick-Film is a precisely coated, capillary film version of Ulano’s

best-selling QTX® direct emulsion. Like QTX, CDF/QT Thick-Film utilizes pure

photopolymer (SBQ) technology to assure extended shelf life and minimal influences

from heat and humidity, the fastest possible exposure speed, good imaging

properties, and on-press durability. Generally, CDF/QT Thick-Film is adhered

to fabric with QTX using the direct/indirect application technique. CDF/QT

Thick-Films can be laminated to produce unlimited stencil thickness variations.

CDF/QT Thick-Film is a precisely coated, capillary film version of Ulano’s

best-selling QTX® direct emulsion. Like QTX, CDF/QT Thick-Film utilizes pure

photopolymer (SBQ) technology to assure extended shelf life and minimal influences

from heat and humidity, the fastest possible exposure speed, good imaging

properties, and on-press durability. Generally, CDF/QT Thick-Film is adhered

to fabric with QTX using the direct/indirect application technique. CDF/QT

Thick-Films can be laminated to produce unlimited stencil thickness variations.