Indirect films offer superior fine detail reproduction; sharp printing edges; uniform

stencil thickness; predictable standardized exposures; close control of

stencil thickness, hence ink deposit; fast and simple stencil production;

and easy stencil removal for efficient mesh recovery. All Ulano gelatin-based

Indirect Films are totally solvent resistant. The topcoat

on Ulano Indirect Films prevents tackiness underconditions of heat and high humidity.

Indirect films offer superior fine detail reproduction; sharp printing edges; uniform

stencil thickness; predictable standardized exposures; close control of

stencil thickness, hence ink deposit; fast and simple stencil production;

and easy stencil removal for efficient mesh recovery. All Ulano gelatin-based

Indirect Films are totally solvent resistant. The topcoat

on Ulano Indirect Films prevents tackiness underconditions of heat and high humidity.

Ulano Gelatin Indirect System Photographic Films provide the ultimate in stencil

resolution and definition. The film is exposed, developed in A + B solution

to harden the exposed aread, (except Ulanolux UP3 and Pulsar), washed out

and adhered to the mesh of a screen. After drying and blocking out, the transparent backing is removed.

All

Indirect System Photographic Films consist of a light-sensitive emulsion

coated on a transparent base or backing sheet, with special adhesives.

All

Indirect System Photographic Films consist of a light-sensitive emulsion

coated on a transparent base or backing sheet, with special adhesives.

Indirect Films, (sometimes referred to as transfer films), are ideal

for applications involving shorter (2,000 - 4,000 impressions) printing runs,

fine details, and excellent definition; and for easy, reproducible, clean

stencil production.

EXPOSURE TIPS

Underexposed: Stencil will be thin (and look thin) resulting

in poor press endurance. Underexposing for resolution much finer than the

job you will print sacrifices durability.

Overexposed: Stencil will be thick (and look thick) resulting

in poor adhesion due to overhardening.

Benefits

- Press-ready stencils in as little as 30 minutes

- Stencil thickness, hence ink deposit, can be adjusted by exposure

- Superior solvent resistance

- Dimensional stability of backing material promotes excellent registration

- Humidity-protective topcoat layer guards against tackiness

under humid conditions

- Completely phthalate free

- Simple handling requirements

- No messy chemicals, no liquid emulsions

- No darkroom or soft-blanket vacuum frame required

- Presensitized

- Stencil can be examined before transfer to screen

- Excellent storage properties

- Fast, easy stencil removal

- Optical flatness of support layer promotes excellent definition for

line and halftone work.

* Longer rolls available upon request.

Gelatin-Based

Photographic Films

Gelatin-Based

Photographic Films

Red gelatin indirect system photographic stencil film with wide processing latitude, excellent edge definition and high resolution. Suitable for a wide range of applications including graphics and electronics.

Resolution: 40 - 60 microns

More Quasar R 100 Info

More Quasar R 100 Info

Ulanoprex®

Light blue gelatin coating on 2-mil optically

flat polyester backing. Fast exposing. Suitable for negative

printing and fine halftone work. This is our finest film.

Superb resolution (30 - 50 microns).

Super Prep®

Green coating on a 2-mil optically flat polyester backing.

Wide exposure latitude. Hides dust, tape marks and positive edges very well,

minimizing the need for touchups. Excellent adhesion to all synthetic meshs.

Not intended for high resolution applications, but suitable for general

graphics work. Resolution: 100 - 125 microns (4 - 5 mils).

SP213 40" X 300" 6 18 LBS.

SP302 44" X 150" 6 15 LBS.

SP313 44" X 300" 6 21 LBS.

Blue

Poly-2®

Blue

Poly-2®

Blue, medium thickness emulsion on a 2-mil optically

flat polyester backing. Combines wide exposure latitude with excellent resolution.

Ideal for general screen printing work. Resolution: 75 - 100 microns (3

- 4 mils).

BP2202 40" X 150" 6 13 LBS.

Blue Poly-3®

A blue, medium thickness emulsion on a 3-mil optically

flat polyester backing. Same as Blue Poly-2, except for the thicker backing,

which affords additional dimensional stability and easier handling of large

stencils. Slightly less resolution than Blue Poly-2. Resolution: 87 - 112

microns (3.5 - 4.5 mils).

BP3202 40" X 150" 6 16 LBS.

BP3213 40" X 300" 6 24 LBS.

BP3302 44" X 150" 6 16 LBS.

BP3313 44" X 300" 6 26 LBS.

Red TI®

A dark red film with a thick emulsion on a 2-mil optically

flat polyester backing. Produces a thick stencil that adheres well to all

meshs, yet has extremely high resolution and definition and wide exposure

latitude. Thin topcoat for use with automatic developing machines. Ideal

for fine line and halftone work and a wide range of electronic printing

applications, especially solder mask.

Resolution: 50 - 75 microns (2 - 3 mils).

UPT 14213 42" X 300" 6 20 LBS.

UPTI 4231 42" X 600" 6 52 LBS.

Evaluating Light Sources

Fiat lux! (“Let there be light!”), one of the earliest proclamations

in the Book of Genesis, should be one of your first considerations in the creation

of photographic stencils. Light sources have three main attributes. Insofar

as a light source optimizes each attribute or not, it will produce stencils

ranging from superb to poor.

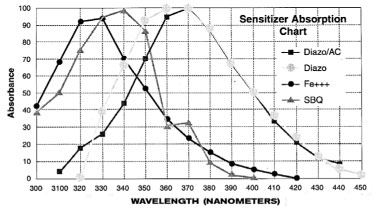

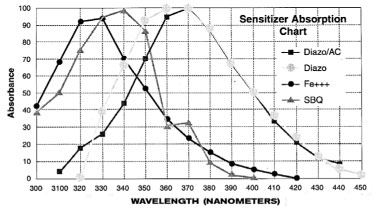

SPECTRAL OUTPUT

The wavelengths of light, or spectral output, of an exposure source should

match closely the spectral sensitivity of photo stencil materials. The closer

the match-up, the more efficient the light source, and the better it will “cure” or

cross-link the molecules of the stencil material, so that the stencil will

be more durable. The common sensitizers used in photo films and emulsions have

specific sensitivity ranges, as shown on the “Sensitizer Absorption Chart” (below).

It’s a common misconception that photographic stencil materials are “UV-sensitive.” In

fact, they are sensitive to light ranging from upper-ultra-violet through the

visible blue part of the spectrum. (That’s why yellow lights make good

safelights, because photo stencil materials don’t react to the longer

wavelengths of yellow.)

LIGHT INTENSITY

Photo stencil materials, even those comparatively fast ones formulated for

projection exposure, are not nearly as fast exposing or sensitive as camera

film. If photographic stencil materials were made that fast, they would be

virtually impossible to protect from “pre-exposure.” Thus, light

sources need the power, the intensity, to expose stencils in a reasonably productive

amount of time.

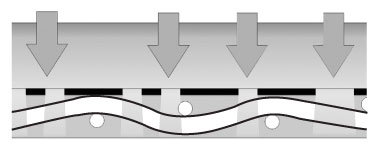

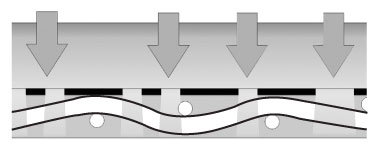

LIGHT GEOMETRY

Light geometry concerns the angle of incidence of light rays as they strike

the artwork and pass through its “clear” portions into the photo

stencil material. Light rays emitted from a small area or “point source”--at

a minimum distance of 1½ times the diagonal of the stencil--are more

nearly perpendicular as they meet the artwork and stencil (“Perpendicular

Light Incidence,” back page). This affords better transfer of image and

non-image information from the artwork into the photo stencil material.

By contrast, with a widely dispersed light source such as fluorescent tubes,

light rays enter the stencil material at oblique angles, quite literally angled

behind the dark edges of the artwork, reducing the fine detail or resolution

of the stencil (“Wide Angle Incidence”).

We categorize light sources according to how well they provide the three key

exposure attributes. The highest quality light sources are metal halide or

carbon arc. Mercury vapor and pulsed xenon are of medium quality. Quartz lamps,

fluorescent tubes. Grolites®, fotoflood bulbs, etc. have problematic deficiencies,

though they can be quite adequate for low resolution work, or in shops that

don’t need high stencil throughput.

"Perpendicular" Light

Incidence

"Perpendicular" Light

Incidence

Wide

Angle Incidence (fluorescent tube unit, top)

Wide

Angle Incidence (fluorescent tube unit, top)

All is not lost if you have a poor light source, but you will have to work

smart to compensate for it, and understand and accept the limitations imposed

by it. For help in making the most of your light source, contact Ulano Technical

Services, Brooklyn, at 1-800-221-0616. Fiat lux!

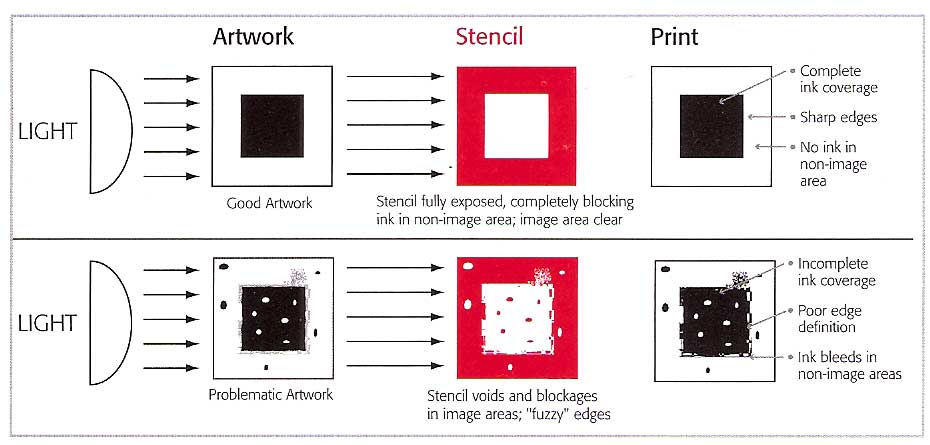

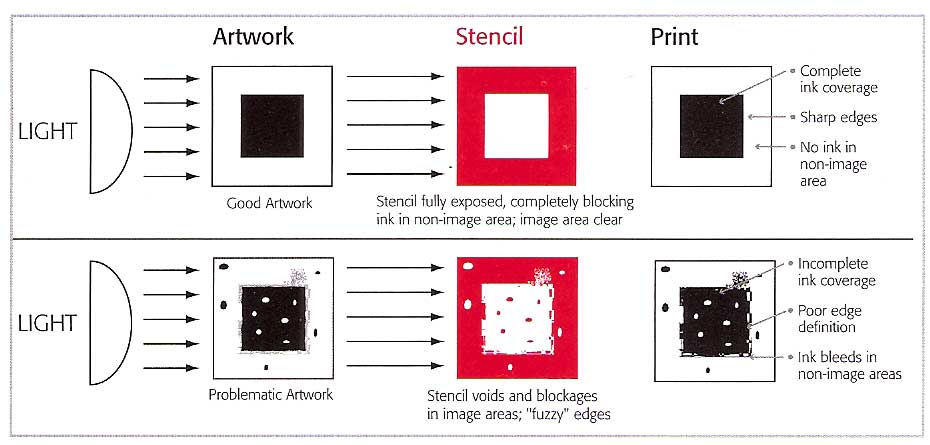

D-max, D-min, and De-lineation: Evaluating Artwork

By “artwork,” we mean any imaged media placed between a light source and photo-stencil film or emulsion during exposure. Most photographic stencils are contact exposed in a vacuum frame, so the dimensions of the artwork are the same as those of the stencil and the final print. Image setter-exposed silver film (right-reading photographic positives*), laser toner (usually on vellum), inkjet on inkjet film, thermal images, and knifecut masking film (Rubylith® brand)—all

are commercial media used for contact exposure.**

The essence of screen printing is a stencil that blocks the flow of ink

to non-image areas of the print and is “open” in image areas, allowing ink to flow freely through the fabric. The integrity of the stencil material and the uncompromised openness of the image areas are equally essential. In addition, there should be a clear demarcation between image and non-image areas. These attributes originate with the artwork.

Photo stencils can never be better than the artwork

used to generate them, nor can the final print be better than the stencil. If the “dark” areas of the artwork lack sufficient density*** to block light during exposure, or if they contain pinholes or ‘thin spots,” stencil material will harden in what should be the open, image areas of the stencil, and ink will not flow readily through the image areas of the stencil during printing. Similarly, if “clear” areas of the artwork are, at best, translucent rather than transparent, or contain “artifacts” such as dirt or dust, light energy will be filtered or blocked before it reaches the stencil material; non-image areas of the stencil won’t be fully “cured” or cross-linked and may break down during the printing run. Finally, if the delineation of image and non-image areas is pixilated, fuzzy, or lacking in acutance (edge sharpness or “definition”),

so will the image edges on the final print.

*Any text or other information should

be on the emulsion side of the positive and appear as you will want it to

look on the final print; the emulsion side of the positive is placed against

the stencil material during exposure.

**Projection exposure requires silver

film positives that are considerably smaller than the final size of the

print. Such positives must be of very good quality, as projection by its

nature enlarges imperfections. “Computer-to-screen” systems don’t use “artwork” as we’ve defined it here. These systems either apply an image in inkjet wax directly to the stencil material (“inkjet CTS”) or utilize Texas Instruments’ digital light processing (DLP®) system to expose a screen “pixel by pixel” (“digital direct exposure”).

***The “dark” and “clear” areas of artwork can be measured on a densitometer. The opacity of the dark areas is referred to as D-max (maximum density) followed by the numeric densitometer reading. D-min refers to the minimum density—which

is a measure of the clarity of the artwork. D-max 4.0 is ideal for stencil

making, as it allows full exposure of non-image areas even if the artwork

medium is cloudy or fogged.

Indirect films offer superior fine detail reproduction; sharp printing edges; uniform

stencil thickness; predictable standardized exposures; close control of

stencil thickness, hence ink deposit; fast and simple stencil production;

and easy stencil removal for efficient mesh recovery. All Ulano gelatin-based

Indirect Films are totally solvent resistant. The topcoat

on Ulano Indirect Films prevents tackiness underconditions of heat and high humidity.

Indirect films offer superior fine detail reproduction; sharp printing edges; uniform

stencil thickness; predictable standardized exposures; close control of

stencil thickness, hence ink deposit; fast and simple stencil production;

and easy stencil removal for efficient mesh recovery. All Ulano gelatin-based

Indirect Films are totally solvent resistant. The topcoat

on Ulano Indirect Films prevents tackiness underconditions of heat and high humidity. All

Indirect System Photographic Films consist of a light-sensitive emulsion

coated on a transparent base or backing sheet, with special adhesives.

All

Indirect System Photographic Films consist of a light-sensitive emulsion

coated on a transparent base or backing sheet, with special adhesives. Gelatin-Based

Photographic Films

Gelatin-Based

Photographic Films

Blue

Poly-2®

Blue

Poly-2®